- Description

- Specs

- DOCUMENTS

- features

Splitter NDT Inc. is extremely excited to introduce our brand new liquid penetrant inspection system, the LP1. This will be the first of 3 standard penetrant inspection systems available from Splitter NDT.

The LP1 is the ideal stand alone liquid penetrant inspection station for the low to medium volume user. Ideally suited for aircraft maintenance facilities, nondestructive

testing labs, NDT schools and training institutes, government and military facilities, and more!

This system is designed with the needs of our client in mind. Extremely durable, user friendly and cost effective, making the LP1 the new go-to system in the industry

Ideal For:

- NDT Training Institutes and Classrooms

- Aircraft Maintenance and Overhaul facilities

- Small to Medium Size Parts

- NDT Service Providers with low-medium throughput

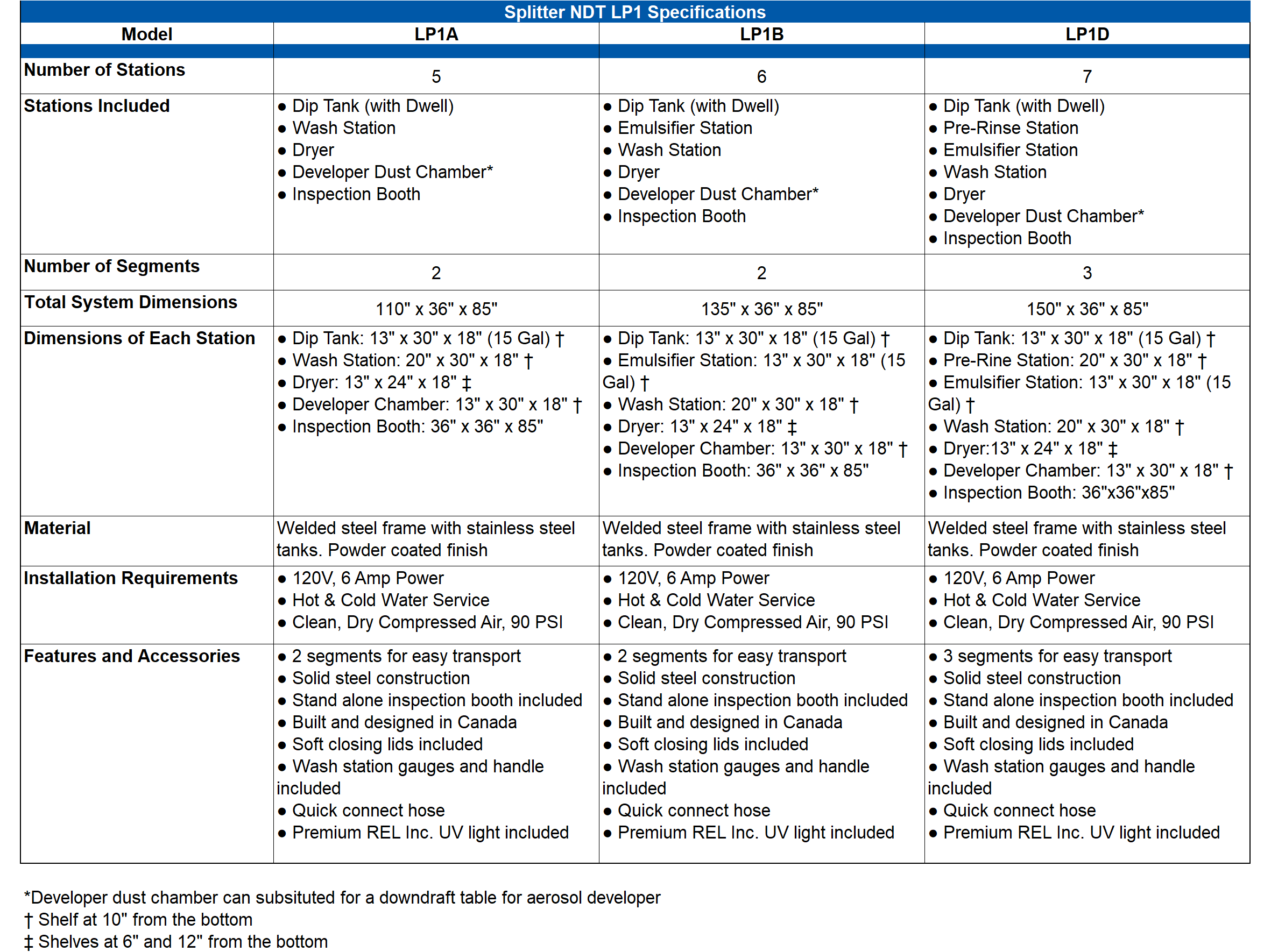

LP1A is designed for method A liquid penetrant inspection

- Includes 5 stations; Dip tank (with dwell), wash station, dryer, developer dust chamber, inspection booth

LP1B is designed for method B liquid penetrant inspection

- Includes 6 stations; Dip tank (with dwell), emulsifier station, wash station, dryer, developer dust chamber, inspection booth

LP1D is designed for method D liquid penetrant inspection

- Includes 7 stations; Dip tank (with dwell), pre-rinse station, emulsifier station, wash station, dryer, developer dust chamber, inspection booth

Highlights

- All-in-one system

- Built in 2 (or 3) segments for ease of transport

- Separate wet end + dry end

- Available for all LPI methods

- Designed and built in Canada

Features

- High quality design and construction

- Built with a powder coated steel frame and stainless steel stations

- Soft close tank lids

- Full size, walk-in inspection station

- Quick connect wash station hose

- REL Inc. UV-A light included

- Dryer and developer dust chamber. Dust chamber can be replaced by a downdraft table

- System accessories included

- tank lid

- water gauges

- UV-A Light

- Discounted start-up kits available